Optimized

Metallurgy

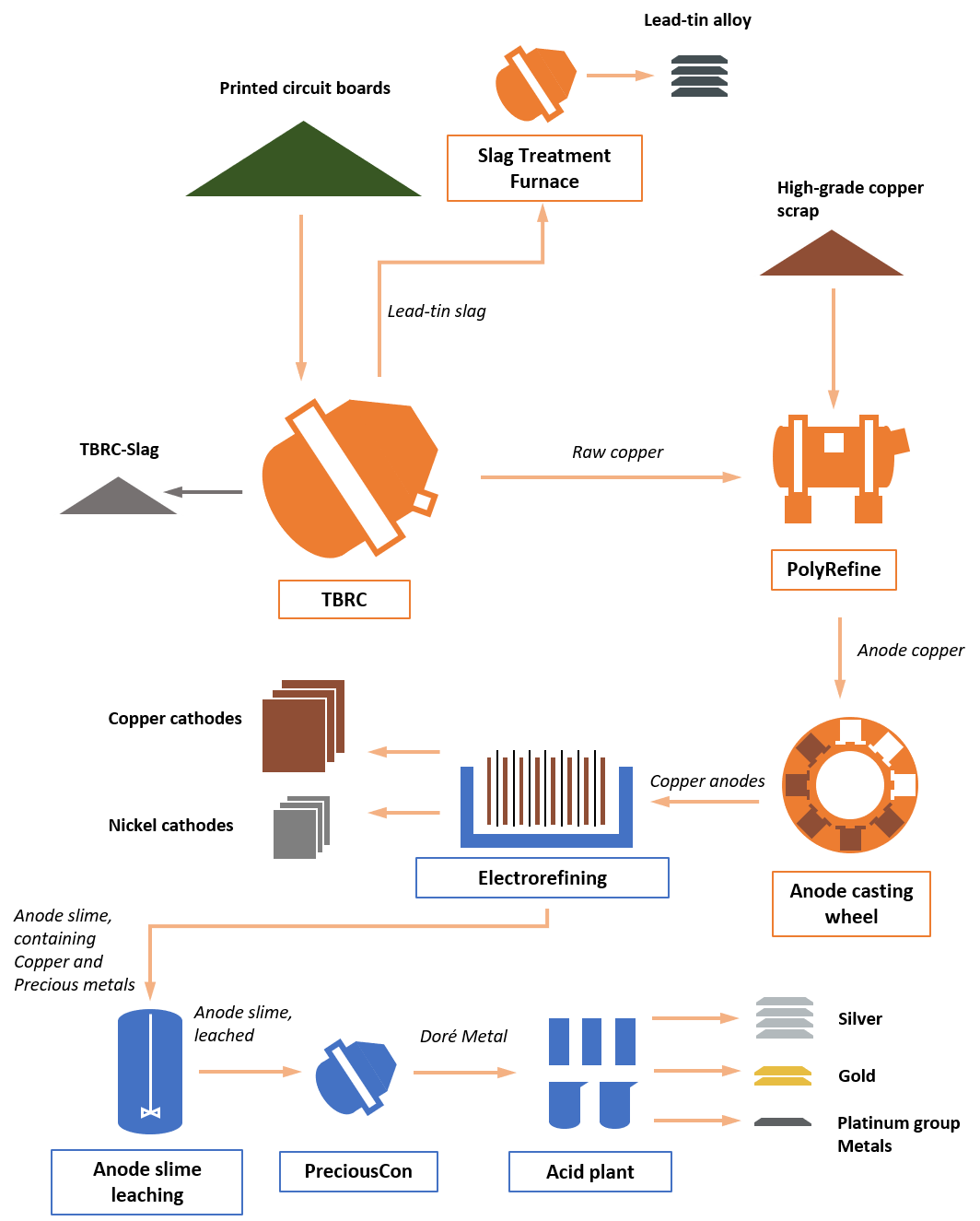

The UrbanGold Compact process route was initially developed for processing printed circuit boards (PCBs). Now it is a state-of-the art technology for the recovery of base metals and precious metals from any kinds of higher quality scraps. It consists of a TBRC as the primary smelting vessel, optionally extended by the required pre-treatment steps – such as shredding and sorting.

Both pre-treatment and further processing are tailored according to individual raw material portfolios and desired product characteristic. The produced metal from smelting and refining is cast into anodes and further refined in a hydrometallurgical plant.

Especially attractive is the possibility of a later extension to a full UrbanGold Flex plant.

CHALLENGE

- Scrap from printed circuit boards (PCBs) is high in precious metals – metallurgical recycling therefore of special interest

- Selling scrap to large scale plants is involved with significant discounts from the incorporated value

- PCB smelting is complex – achieving a high efficiency requires both a suitable plant and profound metallurgical know-how

SOLUTION

- UrbanGold Compact for processing PCB scrap from several hundred to tens of thousands of tons per year, including the possibility of adding mid- and high-grade scraps

- Production of intermediates or technically pure copper, nickel(compounds), precious metals (…)

BENEFIT

- Compact entry into the world of e-waste recycling

- Extensible to UrbanGold Flex plant

- Modular and customer tailored design

- All-inclusive solution with equipment, auxiliaries, turn-key portion, process, start-up, and training

- High automation grade

- Production of easy marketable products