UrbanGold's

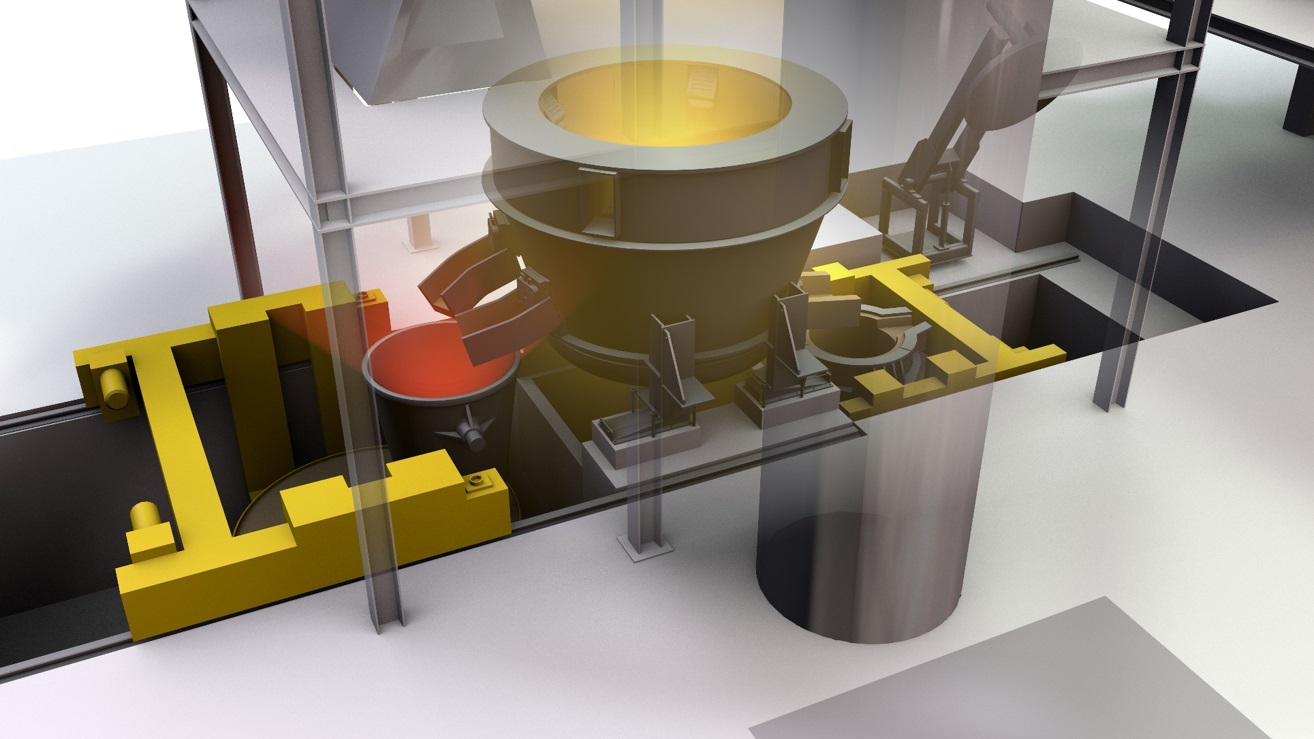

HENRI Smelter

As primary smelting furnace within the pyrometallurgical facilities, the HENRI represents the centrepiece of the UrbanGold Flex recycling technology. The pyrometallurgical treatment carried out in this unit ensures an enrichment of valuable metals in a metallic phase and a separation of organic compounds and metallic impurities. The HENRI is designed to process up to 100% of e-waste fractions and therefore must meet the following requirements:

- Managing high amounts of organics in the feed material and the correspondingly high energy input

- Managing the input of halogens as part of the organic fractions

- Managing the input of aluminium and aluminium oxide

- Effective reduction work to maximize metal yield and generate a slag with minimal valuable metals content

- Maximum flexibility in respect of feed material composition

- High availability and minimum downtime for maintenance

The HENRI is a highly specialized smelting furnace based on the bath smelting technology, which is well established in the copper, lead, and zinc industry. Depending on the requirements of each individual application it will be customer-tailored and adapted accordingly. The range starts at a simplified and partly manually operated “HENRI MiniSmelter” for some tonnes per batch and ends at an almost fully automated large-scale unit within an UrbanGold Flex plant for 100,000 tonnes of raw material per year or even more.

CHALLENGE

- Conventional smelting vessels are not optimized for e-waste recycling

- Especially low-grade fractions cause problems during furnace operation

- Several challenges – as there are the heat balance, slag chemistry, furnace atmosphere (…) need to be addressed

SOLUTION

- A highly specialized smelting vessel based on the established bath smelting technology

- Highly modular design for numerous applications and raw material mixes

BENEFIT

- Customer tailored design for each individual application

- Highest flexibility in respect of raw material mix and processing capacity

- Optimized waste heat recovery and most modern off-gas treatment for minimizing environmental impact

- Specially designed metallurgy and maximized extraction efficiency